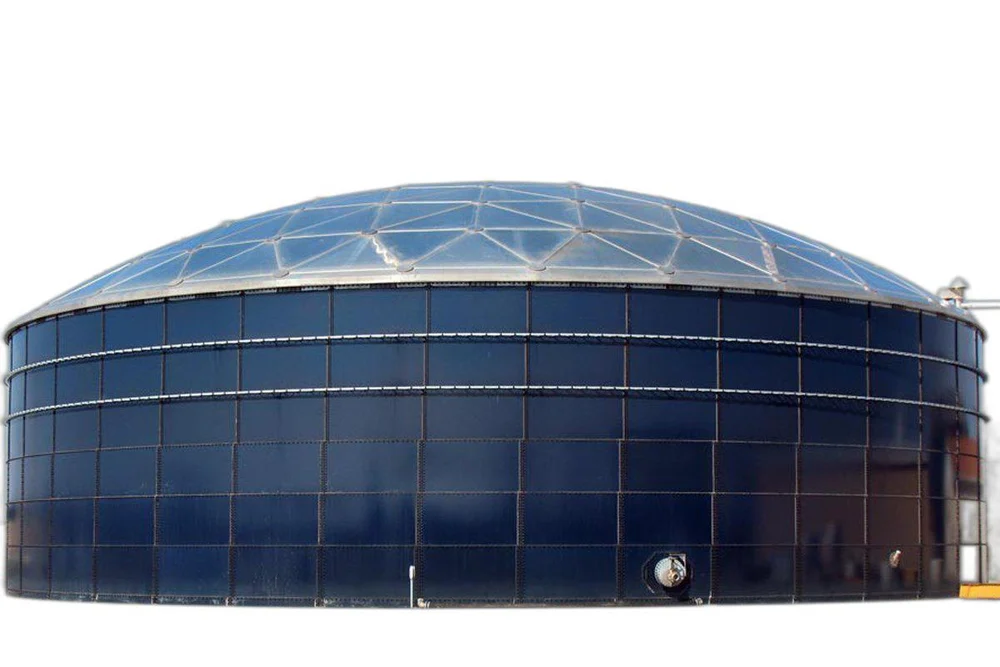

Glass Fused to Steel Liner / Sealant TankGlass Fused to Steel Liner / Sealant TankGlass Fused to Steel Liner / Sealant Tank

Previous slide

Next slide

GFS-900V GLASS FUSED TO STEEL TANKS

GFS-900V Glass Fused Bolted Steel Tanks are a type of tank that is highly resistant to corrosion and abrasion. It is made by fusing a layer of glass onto a steel substrate, creating a durable, impermeable barrier that protects against harsh chemicals, weather conditions, and other external factors.

Fine Touch Steel

glass lined bolted steel tanks are ideal for a variety of applications, including water storage, wastewater treatment, and industrial process tankage. In addition, our glass fused to steel tanks offer significant cost savings compared to other types of storage tanks.

If you are looking for reliable glass lined steel tank manufacturers, don’t hesitate to contact us. We provide installation services as well as GFS-900V glass-fused-to-steel tanks.

All Products

Grain Storage

Storage tanks

Material Handling equipment

turnkey project

How can we help you?

Contact us at the Consulting WP office nearest to you or submit a business inquiry online.

GFS-900V GLASS FUSED TO STEEL TANKS

-

Excellent anti-corrosion performance

-

Fast installation with better quality: design, manufacturing, and quality control in the factory

-

Safe, skill-free: less working aloft, no need for long-time worker training

-

Maintenance-free and easy to repair

-

Less influenced by local weather

-

Possible to relocate, expand and reuse

-

Beautiful appearance

GFS-900V GLASS FUSED TO STEEL TANKS

| Coating Thickness | 250-450μm |

| Coating Process | 1 mix-coats or 2 coats 2 fires |

| Adhesion | Class 3, (EN 10209:2013) |

| Elasticity | 500KN/mm |

| Hardness | 5.0 Mohs |

| PH Range | 3-9 |

| Holiday Test | 900V |

| Service life | More than 30 years |

GFS-900V GLASS FUSED TO STEEL TANKS

-

Farm Digesters Using Agricultural Waste

-

Farm Digesters using any other Waste Streams

-

Edible / vegetable Oils

-

Dry Bulk Solids

-

Fire Water

-

Potable Water

-

Municipal Sludge Cake Storage

-

Farm Digesters

-

Municipal Sludge Storage

-

Municipal Sludge Treatment

INSTALLATION OF GLASS FUSED BOLTED STEEL TANKS

Finetouch one of the leading glass lined storage tank manufacturers in India, not only provides high-quality glass lined water storage tanks but also offer installation services.

The installation process of Glass Lined Steel Tanks prioritizes foundation stability to securely support the tank body and stored products. Here are the installation steps:

-

Preparation Phase: Clean and level the installation site. Apply a foundation of sand or crushed stone, followed by constructing a circular concrete wall or pad. It’s better that the foundation work can be completed before tank delivery.

-

Construction Phase: Erect tank panels layer by layer from the bottom up. Ensure clean, dry steel plates during bonding and promptly replace any loose bolts. Secure the bottom layer to the foundation with reinforcement bars. Assemble subsequent layers, connecting them with a jack and installing wind braces for stability. Add necessary accessories like valves and doors, and install the tank roof.

-

Testing and Maintenance: Conduct a leak test post-assembly to verify tank integrity and safety. Regular maintenance, including inspections, cleaning, leak monitoring, and damage checks, is vital to prolong the glass coated steel tanks’ lifespan and ensure proper functionality.

Glass fused bolted steel tanks offer advantages over traditional storage solutions, including rapid installation, reduced transportation costs, and the ability to assemble in various weather conditions, minimizing weather-related delays.

Quality Control of GFS-900V Glass Coated Steel Tanks

Fine Touch Steel is committed to providing high-quality Glass-Fused-to-Steel (GFS) tanks, adhering strictly to the highest industry product quality standards.

Fine Touch Steel prioritizes research and innovation, and our independently manufactured GFS tanks were the first in the Asian region to pass the NSF/ANSI 61 standard certification by NSF International. We also led the drafting of Chinese Standard QB/T 5379-2019 for Glass Fused To Steel Tanks, setting the benchmark for the industry in the country.

Fine Touch Steel tanks comply with international standards such as AWWA D103-19, ISO 28765, NSF/ANSI 61, and NFPA to ensure product quality meets global standards. We continually listen to our clients’ needs and feedback, constantly improving product quality to achieve the highest levels of customer satisfaction.

Related Products